We have more than 15 years experience in machining production.we offer you products with good quality and competitive price.

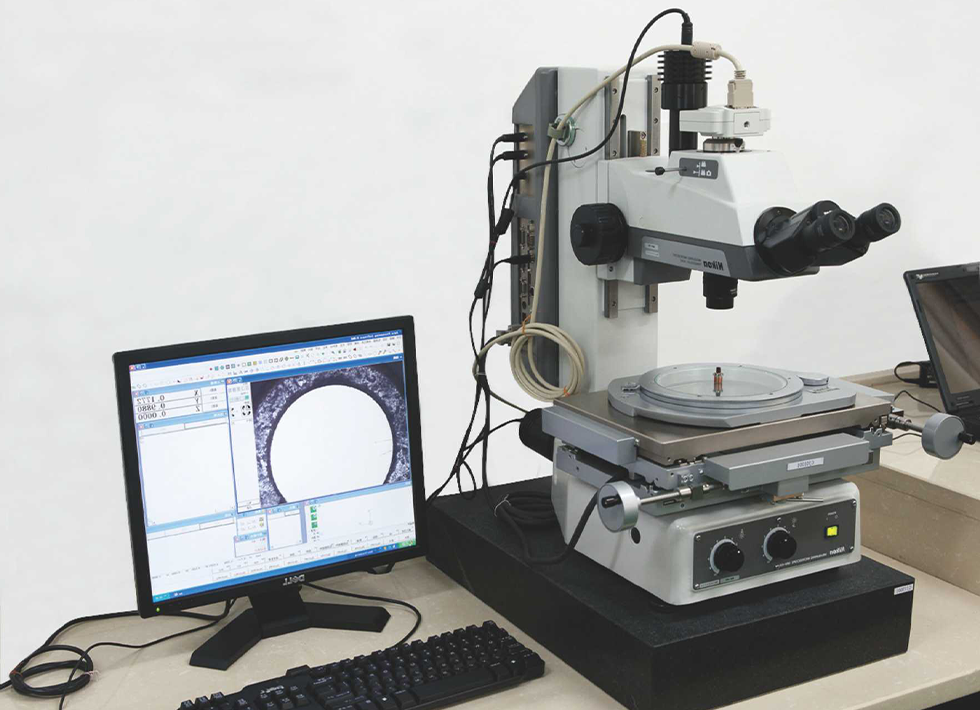

NINGBO JH Metal Technology Co., Ltd. is located in Ningbo City, Yinzhou District, covering an area of 3500 square meters, which has a convenient traffic route, close to the Ningbo International Airport, the deep-water harbor--Beilun port,and Shanghai and Hangzhou-Ningbo Expressway away The company is a manufacturing enterprise , producing machinery such as stamping parts, metal machined parts.Over the years our company has been committed to metal stamping,machineparts manufacturing and processing, with a wealth of development and manufacturing experience,and we have formed strong technical force,as wellas large-scale production. CNC Precision Machining Company and Factory. The company has import and export rights, and about 90% of the products areexported to the United States, Canada, Germany and other countries. The company currently has GB/T19001-2016/ISo 9001:2015, internationalauality manaaement svstem. the company regard the quality as life, with making experienced engineers and specially trained quality control staff check product quality. Adhering to the business development ideas," surviving by good faith, developing by creativity, expanding markets by good service", we sincerely welcome the domestic and international customers as our partners to work together and create brilliant futurel.

We have enough experience to make die casting toolings and produce any kinds of die casting products. From casting process to mechanical machining, Every process is controlled by skilled technicians in strict collaboration. As CNC Precision Machining Factory, We have competitive prices and high quality, so that customers get cost-effective products.We use zinc and aluminum to make our products. Materials are zinc, ADC12, A380 etc. Custom CNC Machining Services.